ELECTRICALLY CONDUCTIVE PLASTICS

PRE-ELEC® — a global leader in conductive compounds

Controlling static electricity

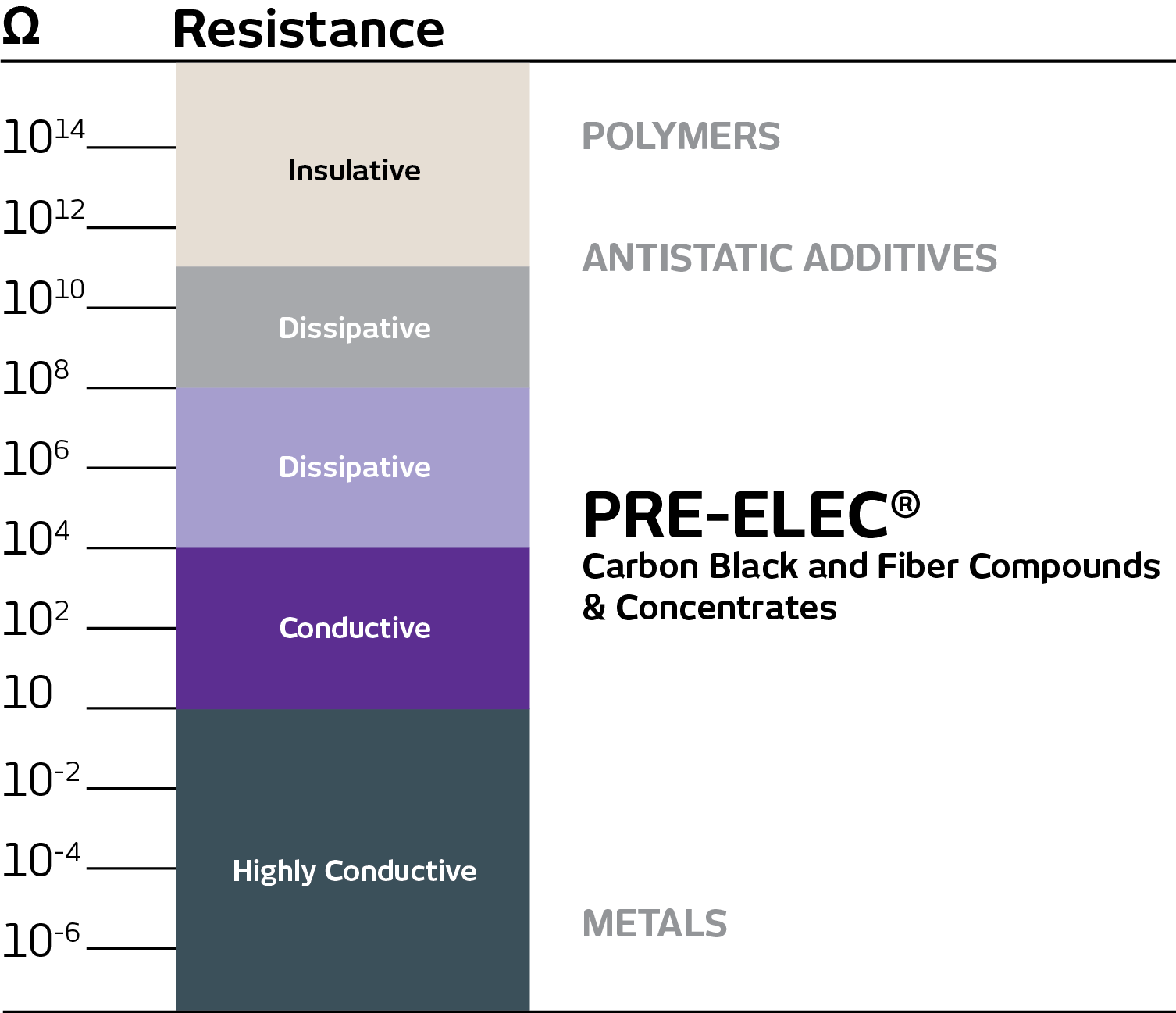

It is possible to add electrical conductivity to plastics with several additives, but carbon black has established its position as the most widely used electrically conductive additive.

Carbon black offers a superior price-performance ratio and stable properties over time. Typically carbon black compounds' surface resistance settles between 102 Ω — 106 Ω.

We introduced our first electrically conductive plastic compound in 1983 as one of the first companies in the world. Today, the PRE-ELEC® product family covers wide areas of the conductivity spectrum and a large selection of base polymers.

Adding carbon black improves conductivity

Carbon black is a highly conductive material with low density compared to metals. By mixing it into plastic, it is possible to gradually alter the plastic's electrical properties to decrease its resistivity. The resistivity of the compound correlates with the average distance between carbon black particles within the plastic matrix.

At a certain loading level called percolation threshold, the carbon black particles are close enough to form an electrical contact, which can be seen as a significant change in the conductivity. Further, carbon black addition increases the conductivity significantly at first and gradually forms a plateau, which is dependent on the conductivity level of the used additive.

Percolation curve. Adding carbon black to plastic decreases resistivity.

Let Mr. Premix and Mr. Statix explain to you how electrically conductive plastics can protect from electric shocks:

More information on how the magic works in our blog post:

INDUSTRY SOLUTIONS

Drivers for using electrically conductive plastics

Protecting against unintentional

electrostatic discharges (ESD)

Protecting components from static electricity during electronics production, transportation, and handling.

Protecting against accidents in

explosive (Ex) environments

Eliminating the static discharges which can cause explosion and fire risks in, for example, the automotive, mining, and process industries.

In addition, plastics' light weight, mass-production capabilities, economicality, and freedom of design bring a lot of value when selecting the source materials.

OTHER FUNCTIONALITIES

PRE-ELEC® is available as

Compounds

Base polymers

PE, PP, PS, ABS, PC, PC/ABS,

ABS, PA6, PBT, TPU, TPE

Processing types

Extrusion

Injection molding

Blow molding

Film blowing

Filament spinning

Pultrusion

Post-processing

Foaming

Thermoforming

Concentrates

Base polymers

PE-HD, PE-LLD, EVA, PP,

PS, PA6

Processing types

Extrusion

Injection molding

Blow molding

Film blowing

Filament spinning

Pultrusion

Post-processing

Foaming

Thermoforming

Other information

Typical concentrate usage ranges from 40 wt-% to 60 wt-% depending on the surface resistance target. Higher dosages are also possible if the process tolerates higher process viscosities.

MATERIAL SOLUTIONS

Boost your business with electrically conductive plastics concentrates

Carbon black concentrates are an excellent way to reduce raw material costs. In PRE-ELEC® concentrates, the carbon black content has been optimized to the highest possible level. When striving for maximum cost efficiency, recycled plastics or regrind from your own process can be used to dilute the concentrate. One small yet innovative step can lead to significant cost savings.

Besides the economic advantages, concentrates also allow the modification of product properties. To impart stiffness and strength to the finished product, the reinforced plastic can be used for dilution.

MORE INFORMATION

Tackling processing challenges

Premix has over 30 years of experience in producing high-quality functional plastics. Our electrically conductive plastics have very good dispersion (even distribution of carbon black in plastic). Overcoming the following challenges is part of our expertise:

PROCESSING INSTRUCTIONS

This material further exaplains extrusion and injection molding carbon black filled electrically conductive compounds and concentrates.