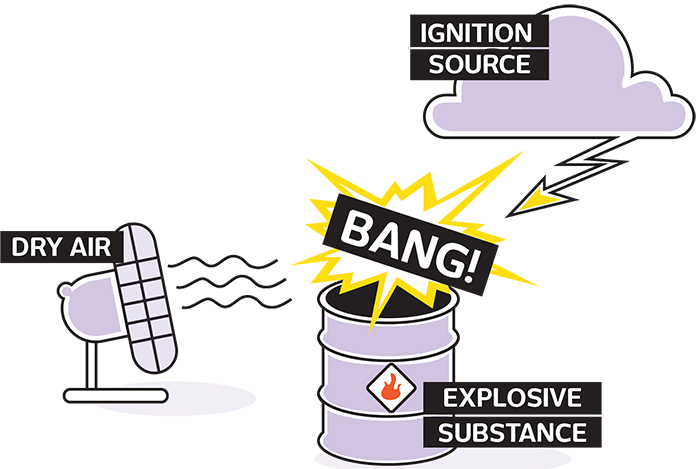

Imagine an environment where the air contains a potentially explosive substance, such as oil or chemical fumes, sawdust, or baking flour. Then, some innocent equipment or an ungrounded person creates a spark of electricity that ignites the substance flowing in the air. People can get hurt in the explosion, and the buildings can suffer damage or even burn down.

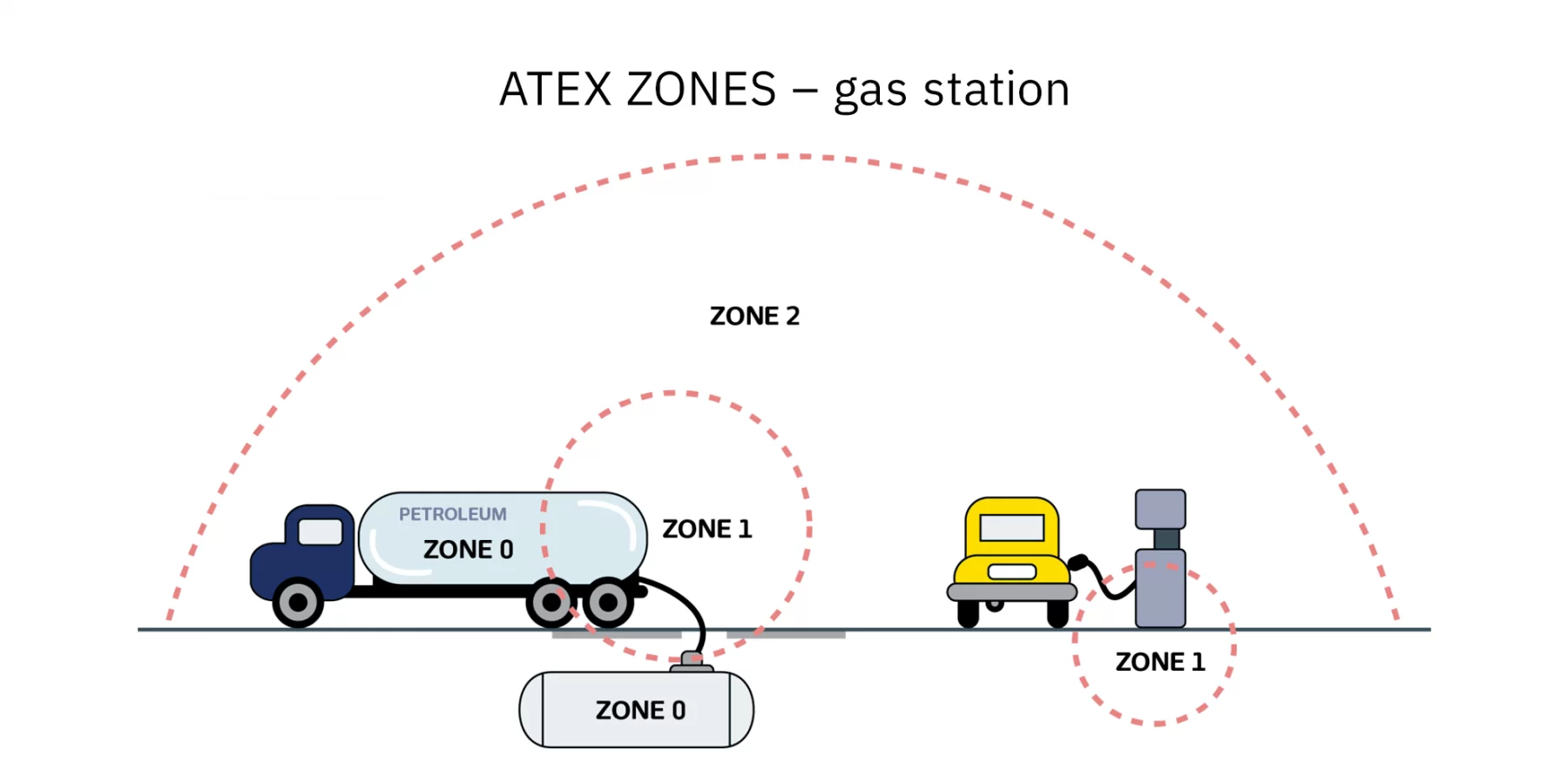

This kind of explosion could happen at a gas station, a coal mine, or a wheat mill. A better-known example is the danger of smoking at a gas station. But many people don't realize that baking flour, for example, can be explosive. Or that electric discharge from an electrically resistant material can ignite an explosion.

MEET US IN ORLANDO IN MAY

Explosive environments

In explosive (Ex) environments, electric sparks are especially dangerous. Explosions can occur when these factors combine:

- Dry air

- Explosive substances in the air, such as

- Oil fumes, gasses

- Dust from agricultural products, such as flour, sugar, cereals, soybeans, rice, etc.

- Dust from coal, medicines, wood, textiles, etc.

- Ignition source (e.g., ESD)

Mines are often explosive environments.

ATEX directive and electrically conductive plastics

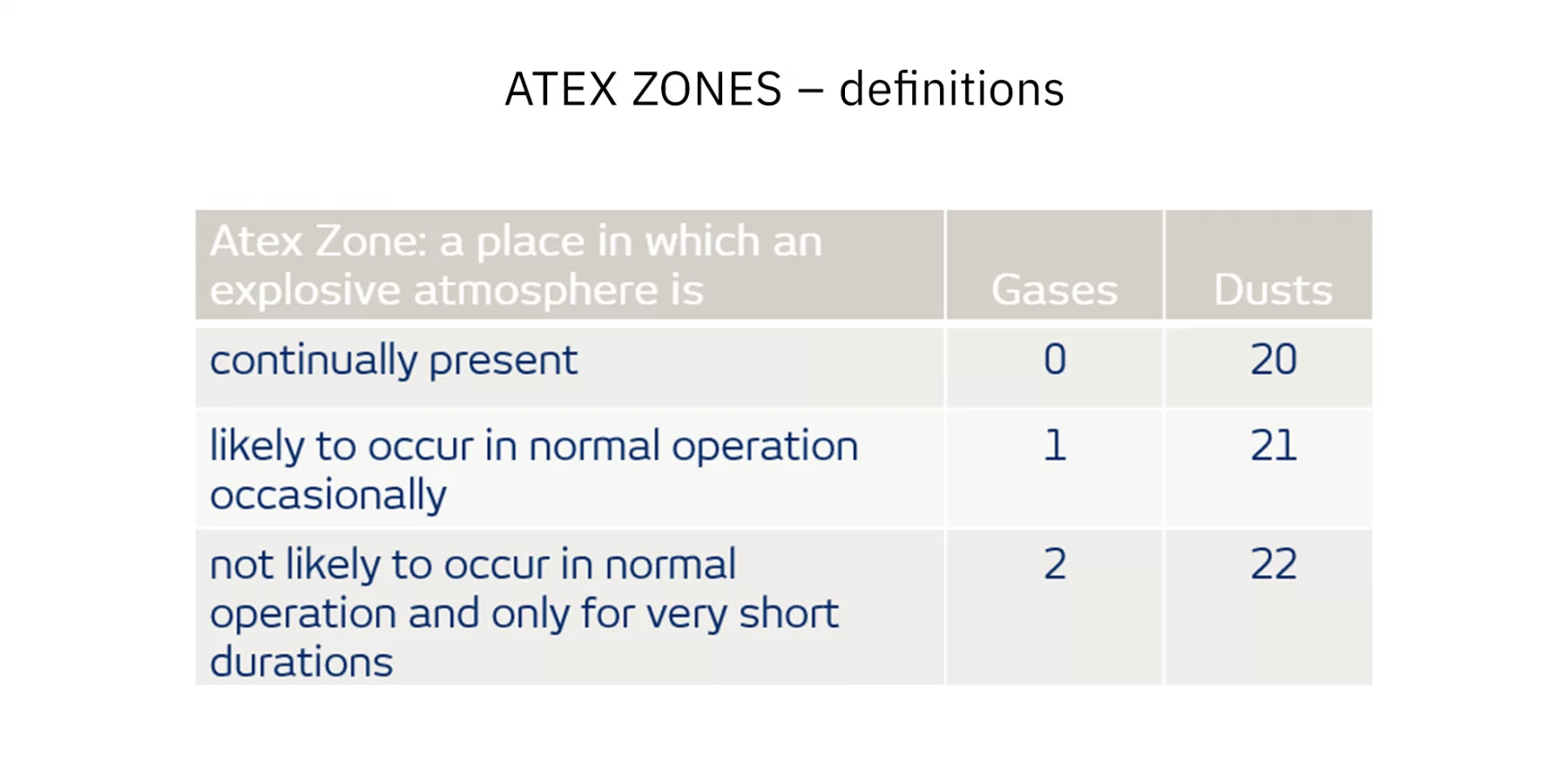

The European Union's ATEX Directive (2014/34/EU) covers equipment and protective systems intended for use in potentially explosive atmospheres. For raw materials, there's no specific directive, but the materials need to be compatible with the requirements for the whole equipment.

Plastics are increasingly being used in ATEX environments to replace heavy, corrosive, and rigid materials, such as metals. However, due to their insulative properties, plastics can cause uncontrolled static discharge, leading to explosions and human casualties. Electrically conductive plastics are an excellent solution for ATEX areas when their surface resistance is <109 ohms.

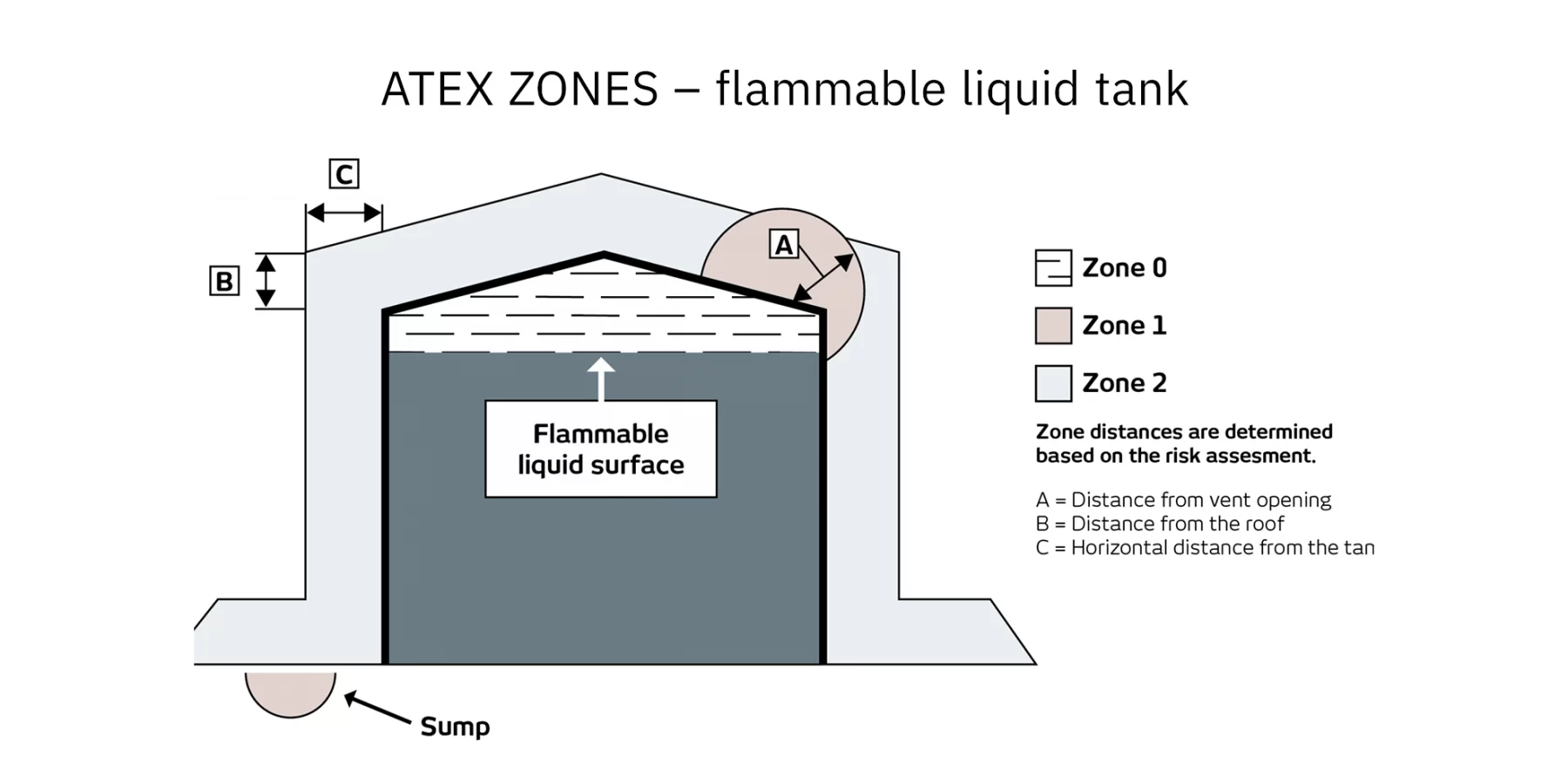

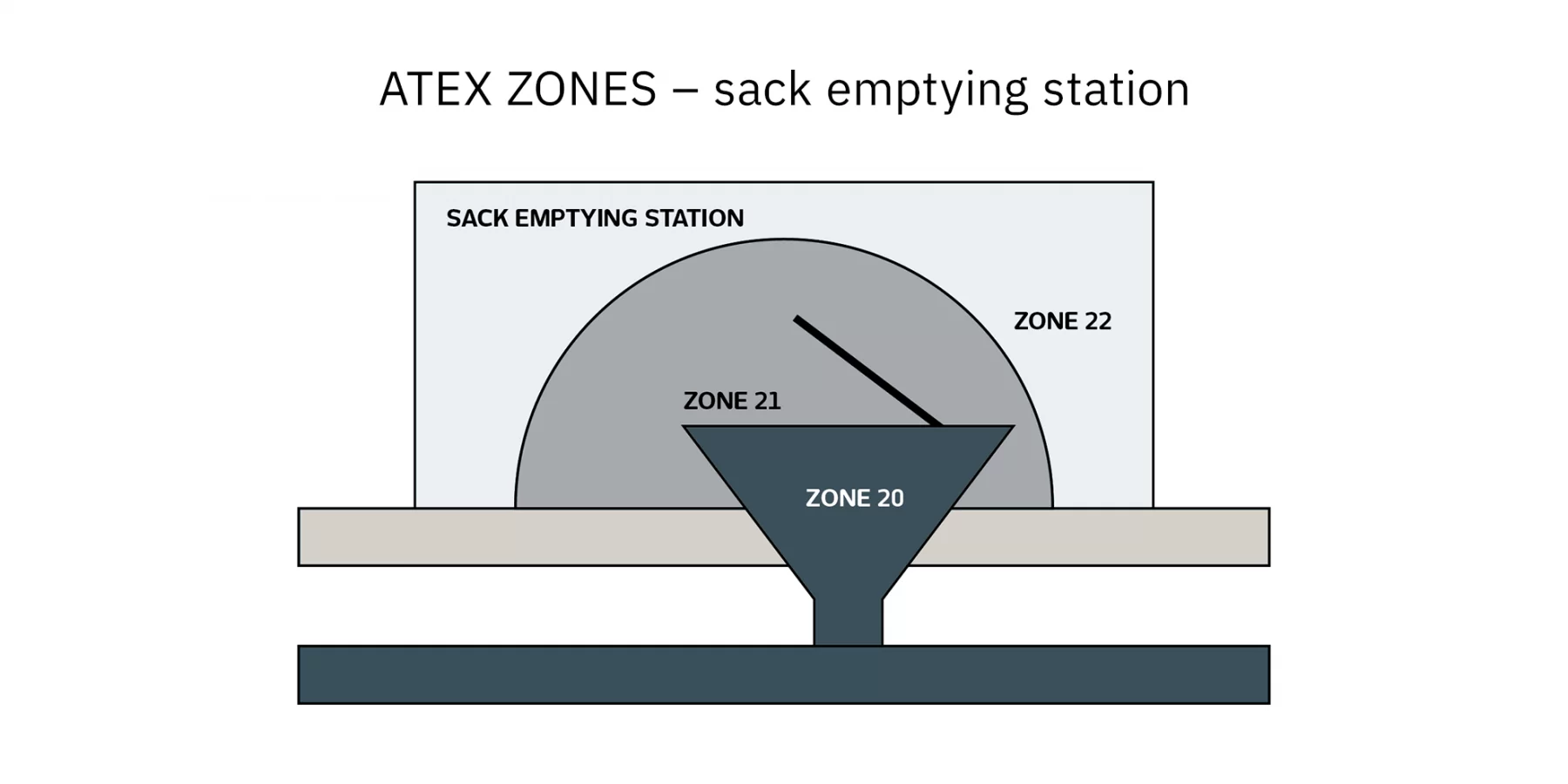

Examples of ATEX environments (click the pictures to open):

Need more information?

CONTACT OUR ATEX EXPERT

Oxana Helenius-Yusupova

Designing ATEX-compatible equipment together with Premix

Premix's electrically conductive PRE-ELEC® plastics typically have much lower surface resistance than 109 ohms, and they can be customized to fulfill the customer's specifications. Compared to metals, plastics are cheaper, lighter, and corrosion-resistant. In addition, injection molding enables freedom in form design. Flame retardancy can be added as an additional property.

Premix already has a wide variety of electrically conductive plastics, and we often develop suitable materials for our customers. From our Data Center, you can find a list of readily offered raw materials with parameters like surface resistance and temperature stability.

Raw materials for ATEX equipment can’t be certified as the whole item must be certified and withstand all the standards according to the ATEX utilization area classification.

INDUSTRY SOLUTIONS

MATERIAL SOLUTIONS

Frequently asked questions (FAQ)

We have collected here some questions on ATEX from our customers and Premix colleagues. Riku Vuorinen, our trusted external expert, has provided the answers. Contact us if you have any further questions!