PACKAGING, STORAGE, AND LOGISTICS

Safer transport, handling, and storage with

PRE-ELEC® electrically conductive plastics

Global Trends

Tightening safety regulations create demand for electrically conductive materials in explosive (Ex) environments.

Increasingly small electronic components need protection from unintended electrostatic discharges (ESD).

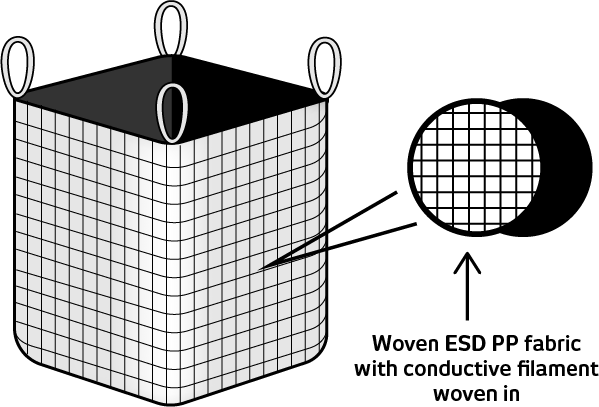

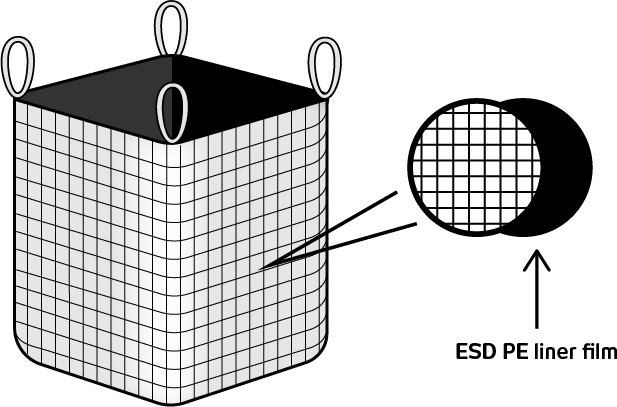

Electrically conductive materials for FIBC applications

Flexible Intermediate Bulk Containers (FIBCs), or big bags, can be made safer by adding electrically conductive plastic films and filaments to their design. These conductive FIBCs, or FIBC type C bags, are made from non-conductive fabrics interwoven with conducting threads. They can be used to transport flammable powders and in spaces where flammable vapors, gases, or combustible specks of dust are present. The conductive inner lining increases the safety of these products.

PRE-ELEC® portfolio

Our portfolio covers materials specially innovated for thin applications. A selection of compounds and concentrates is available for FIBC type C applications (raffia tapes, monofilaments, and films). The material properties of our grades are excellent. We use high-quality raw materials, and the plastic produced is well dispersed and easily processable.

Protect your sensitive components from ESD

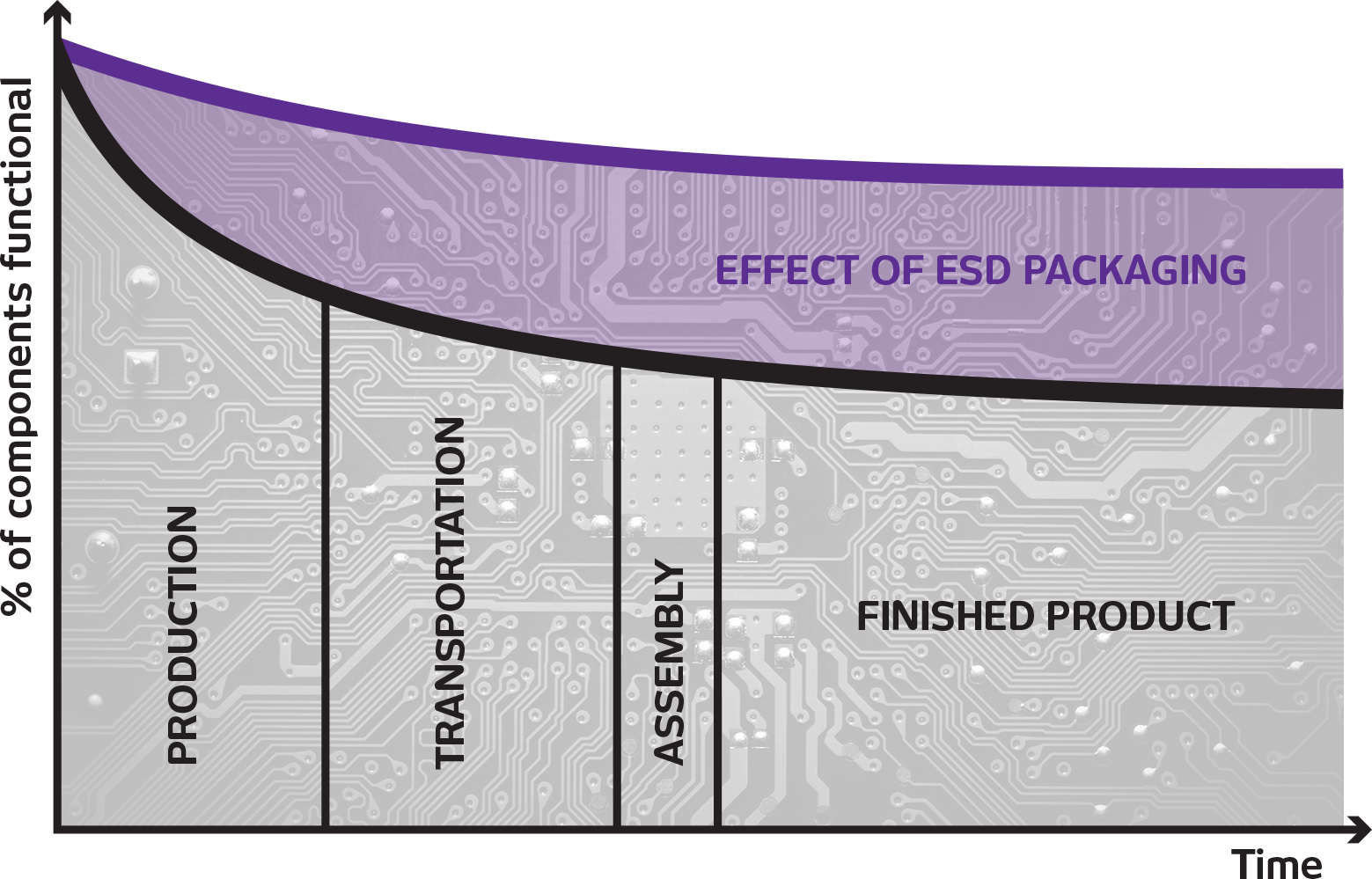

Electronics components need packaging during production and transportation to the customer. Plastics are a commonly used packaging material, but they create a risk of uncontrolled electrostatic discharges (ESDs), which can cause component breakage and hidden failures in them.

PICTURE - Effect of ESD packaging during the life cycle of electronics

Premix's PRE-ELEC® plastics are electrically conductive and static dissipative plastic compounds designed to reduce the extent of hidden failures and guarantee a longer operation life for electronic devices.

The first PRE-ELEC® application was an injection-molded box for a Finnish television manufacturing company in the early 1980s. Since then, we have developed our portfolio of plastics that protect increasingly small and delicate components. Today, we also provide conductive concentrate plastics for ESD package producers, supporting cost-awareness and material recycling.

PRE-ELEC® portfolio

At Premix, we do everything we can to improve the safety of our society – both for people and the environment. Our electrically conductive plastic materials are key factors in improving component safety in the industry.

MEET US IN ORLANDO IN MAY

WHERE TO USE?

MATERIAL SOLUTIONS

Electrically conductive bigbags for explosive environments

Electrically conductive packaging for storing and transporting fragile electronis