Concentrates are an excellent way to reduce overall logistics as a greater amount of functionality can be packed into the same size package.

In PRE-ELEC® concentrates, the carbon black content has been optimized to the highest possible level without impairing processability. To ensure maximum cost efficiency, recycled plastics or regrind from customers' own processes can be used for dilution.

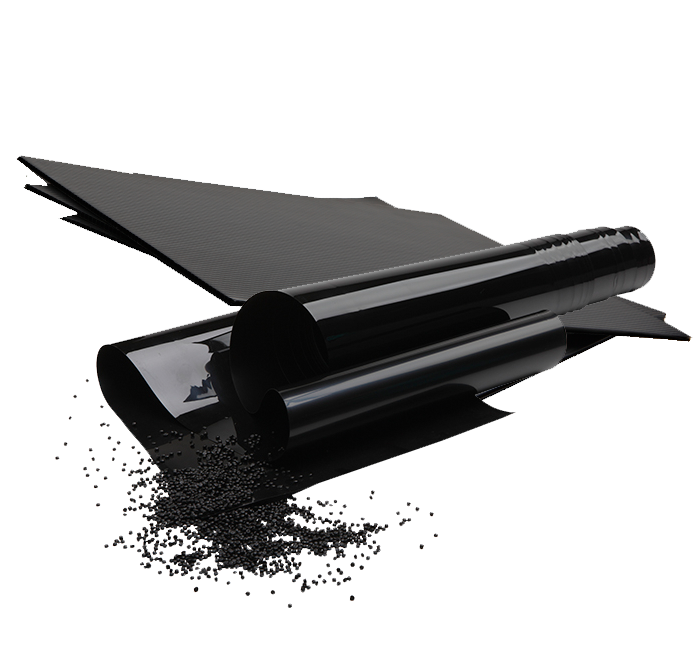

PRE-ELEC® carbon black concentrates

- ecological

- economical

- customizable

Premix’s portfolio offers electrically conductive plastic concentrates for high-volume applications, especially for films, sheets, and filaments. We have concentrates based on many polymers that are used for high-volume applications like film, filaments (incl FIBC type C), fibers, pallets, pipes, drums, trays, cans, etc.

The advantages — Why concentrates?

COMPLEMENTARY MATERIALS

Concentrates can be used for type C bigbags

Films, sheets