Kibron Relies on Premix Materials for Safer, More Reliable Measurements

Kibron chose Premix’s conductive materials to ensure cleaner, safer, and more reliable surface tension measurements.

Background

Kibron Inc. develops high-performance instruments for surface and interfacial tension measurements, making a traditionally complex process faster, more precise, and easier to use. Their tensiometers and Langmuir instruments enable applications ranging from industrial high-throughput screening to portable, battery-operated devices. Known for reliability, sensitivity, and user-friendliness, Kibron’s solutions are trusted in pharmaceuticals, biotech, food, and academic research worldwide.

Challenge

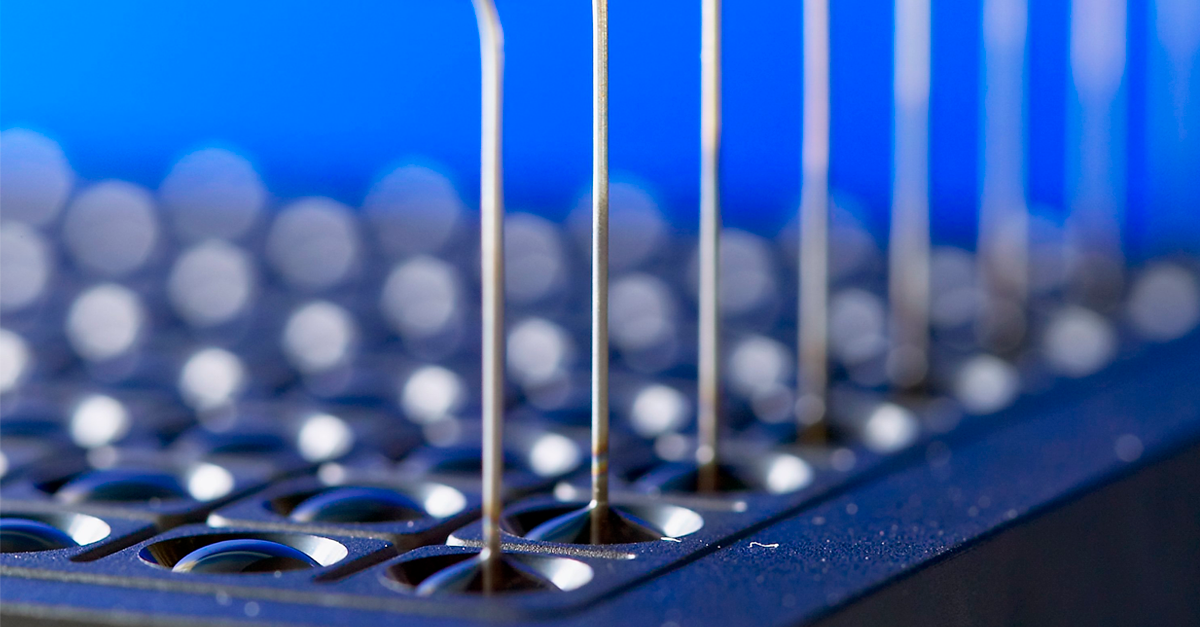

Kibron’s instruments, such as the AquaPi+, EasyPi+ and Delta-8 systems, require reliable consumables for highly sensitive measurements. The heart of these instruments is a highly sensitive force sensor with a sub micronewton resolution. Surface tension measurements are very sensitive to surface active contamination.

Traditional glass cups pose a risk of contamination and require labor-intensive cleaning with aggressive chemicals. To address this, Kibron uses microplates and sample cups made from conductive plastic supplied by Premix, which minimize contamination risks and simplify handling. Another critical factor is static electricity, which challenges the measurement process by introducing additional electrostatic forces between the measurement probe and the surroundings. The conductive material efficiently dissipates any residual charges.

The challenge was to find a material that combines antistatic properties, chemical resistance, and processability in complex part geometries.

Solution

To support these demanding measurements, Kibron relies on electrically conductive polypropylene materials from Premix, specifically optimized for their disposable sample cups and microplates.

“Choosing electrically conductive plastic as a raw material for our consumable sample platforms solved several challenges at once; eliminating the impact of static electricity, improved consistency of the measurement results, and making life easier for both Kibron and our customers.”

Juha-Pekka Suomalainen, Chemist, Ph.D., Managing Director, Kibron Inc.

Key technical features of PRE-ELEC® TP6735

Conductive thermoplastic compound based on medical grade polypropylene. Suitable for injection moulded components and consumables.

- Volume resistivity: < 20 Ωcm

- Surface resistance: < 103 Ω

- Specific gravity: 1.0 g/cm3

- Melt flow index: 16 g/10 min

- Tensile strength: 26 MPa

- Mould shrinkage: 1.2 – 1.5 %

- HDT, 0.45 MPa: 97 °C

- HDT, 1.8 MPa: 57 °C

- Flex Modulus: 1500 MPa

- Color: Black

- Compliant: REACH and RoHS certified, USP Plastics Class VI. Free from DNAase, RNAase and PCR inhibitors.

From Material to Moulded Part

Kibron’s microplates are produced by KB Components Finland Oy (formerly Plastone Oy), an experienced injection moulding company located in Nurmijärvi, Finland. Specialized in medical moulding and operating under the highest quality standards, KB Components has been working with Premix’s PRE-ELEC® TP6735 for many years.

According to KB Components, the material has proven highly suitable for injection-moulded laboratory consumables. They emphasize that to achieve the best outcome and part quality, it is essential to consider the material’s specific properties already during the mould design phase, as electrically conductive PP compounds behave differently from virgin polypropylene.

![]()

Results / Benefits

- Reduced contamination risk – Disposable consumables eliminate the need for glass cleaning and hazardous chemicals.

- Eliminates the effect of static electricity – Electrically conductive plastic sample cups ensure dissipation of electrostatic charges, which is needed in precise force measurements

- Consistent and reproducible results – No errors caused by chemical residues, dust or incorrect positioning

- Efficiency and ease of use – reliable, ready-to-use consumables help laboratories save time and improve throughput.

Download as PDF

Would you like to keep a copy? You can download this case study as a PDF for easy reference whenever you need it.

Explore Our ESD Solutions

From electronics to industrial applications, see how Premix enables reliable electrostatic discharge protection.