CABLE INDUSTRY

Superior performance and stable properties over time with PRE-ELEC® semiconductive compounds

Global Trends in energy transfer

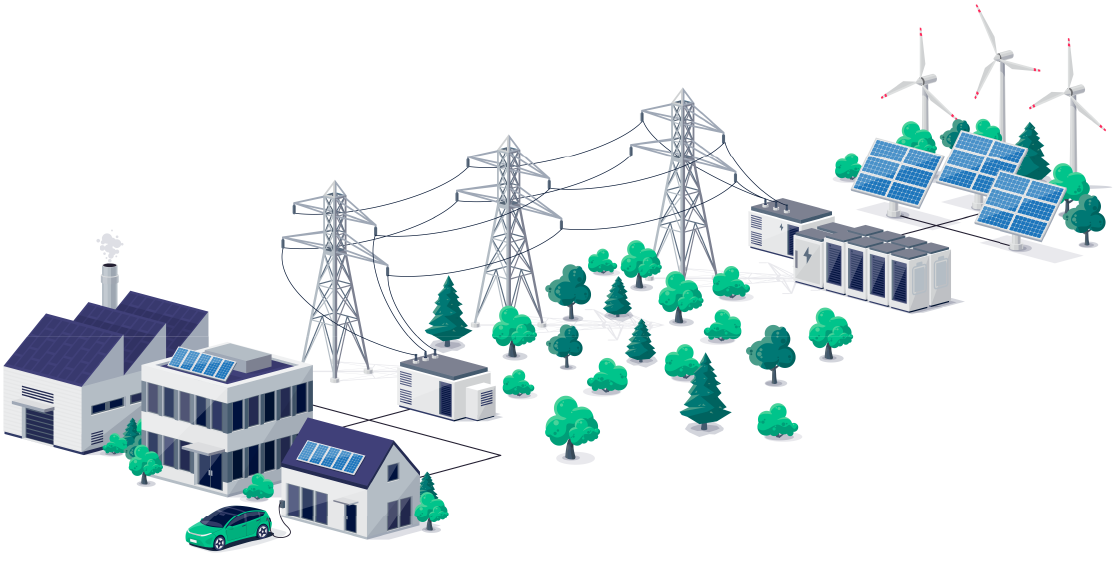

In the next ten years, the whole world will heavily invest in a more electric and carbon-neutral society.

Worldwide electricity consumption is increasing. However, there are still 770 million people without access to electricity in the world (International Energy Agency, 2022). Infrastructure reliability and grid interconnectability are the keys to a sustainable electrical power supply.

The electrification market represents 65% of the world cable market and is expected to grow by +4.3% per annum over the next ten years.

Global megatrends in energy transfer

- Renewable energy generation

- Reliable energy supply: power grid enhancement

- Electrical applications growth

- Digital transformation

The actions to reduce global CO2 emissions and prevent temperatures from rising by more than 1.5°C above pre-industrial levels accelerate and increase renewable energy generation and motivate investments in interconnected power grids.

Demand for cables is growing.

- The grid must manage electricity demand increase and absorb demand peaks.

- The grid also needs to ensure decentralized and intermitted electricity transmissions and enable bidirectional energy flow.

Enhanced power grids need resilient cable solutions

The continuous supply of electricity is a critical factor today. However, electricity supply has become even more fragile due to extreme weather conditions.

- Overhead lines Breakages in the distribution network cause risks for electricity supply but can also cause forest fires and endanger wildlife. These risks can be reduced by covered overheadline cables. Additionally, covered cables enable safety for the environment and installers.

- Underground cables Underground cabling increases the reliability of the distribution network as it is not prone to extreme weather conditions. PRE-ELEC® PP semiconductive compounds are a reliable option for screening.

- Cable accessories

Environmentally friendly material choices play a key role here.

Demands for the grid are growing

Underground cables

Do you want to know more?

Ask from our cable expert, Outi Härkki!

Solutions offered by the PRE-ELEC® portfolio

Longevity and safety

Cables for higher voltages (> 6 kV) need conductor and insulation screens made of semiconductive plastic.

Without these semiconductive layers

- high electrical stresses may cause volatile electrical fields in the insulation, and

- premature breaks can occur

PRE-ELEC® solutions for cables include

- PP semiconductive compounds for conductor and insulation screens

- PE-HD-based compounds for semiconductive jacketing

- Semiconductive compounds with good adhesion to copper and aluminum for sub-sea cables

- Conductive thermoplastics for EMI shielding for signal cables

Cable with a semiconductive screen protects the insulation layer from electric stress

See our PRE-ELEC® Grade Selection for power transmission and special cable applications