CAPACITIVE LIQUID LEVEL DETECTION

PRE-ELEC® electrically conductive plastics are key factors in accurate analyses

The accuracy of liquid handling is an essential topic for diagnostic testing. When a test is carried out, it is of paramount importance that it is trustworthy and accurate.

A single error in the liquid handling process may lead to false positives and false negatives, which may cause various problems in the subsequent steps – at worst, endangering the patients.

Sampling and liquid handling are part of the daily routine at testing laboratories, and if done manually, the chances are high for human error. Modern automatic liquid handling robots can carry out these repetitive chores as programmed, leading to higher sensitivity and specificity in diagnostic testing.

Liquid level sensing is a critical feature in automatic liquid handling. With sensitive and accurate detection of the liquid surface, it is possible to carry out high-precision pipetting of even the smallest volumes and avoid carry-over of liquids, as embedding the pipette tip into the liquid is not needed.

Capacitive liquid level sensing with conductive pipette tips

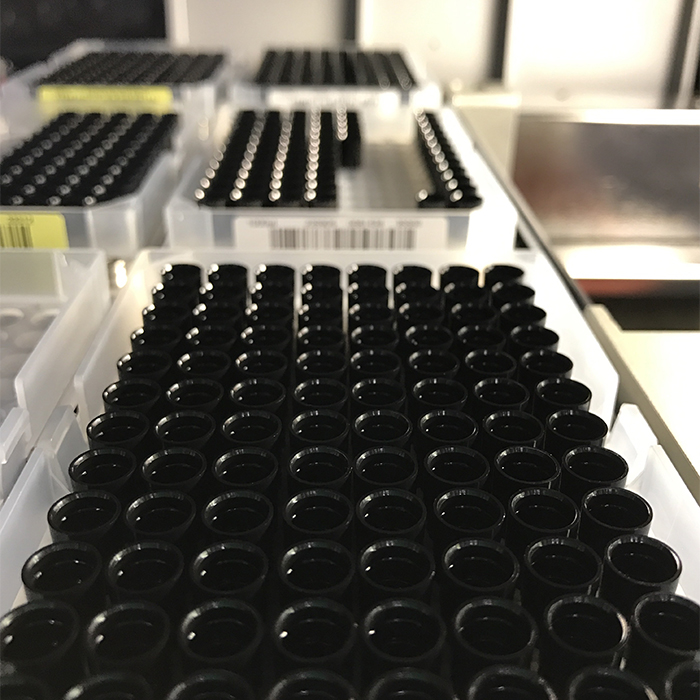

Conductive pipette tips play a key role in capacitive liquid level sensing, the predominant technology in modern automated liquid handling systems. Pipette tips made of electrically conductive plastics enable the measuring of electrical signals at the pipette's tip. Conveniently, the electrical potential changes immediately and accurately as the tip comes into contact with a liquid. It reduces the need to submerge the tip into the liquid to be aspirated. Therefore, the risk of liquid carryover and cross-contamination is reduced significantly. Furthermore, the liquid handling is less dependent on having consistent liquid levels, and the need for laborious programming of the pipetting position is minimized.

To measure liquid level capacitively, the change upon the tip entering a liquid phase needs to be greater than other variances seen in the signal during tip movement. In the case of non-ionic liquids, the capacitance variation is modest, making it harder to utilize well. In these cases, the system is likely operated via pressure-sensing, an option that can also be used in parallel with capacitive liquid-level sensing. Below is an example where a tip traveling at constant speed enters the liquid. The change in capacitance is seen as a sudden shift in the baseline, while pressure takes significantly longer to stabilize and needs to penetrate deeper into the liquid.

A tip traveling at constant speed enters the liquid. The change in capacitance is seen as a sudden shift in the baseline, while pressure takes significantly longer to stabilize, and the tip needs to penetrate deeper into the liquid.

In short, capacitive liquid level sensing provides the following advantages:

- Not sensitive to liquid level

- Minimal liquid contact when aspirating

- Various control modes

MORE INFORMATION

LATEST NEWS

Premix to open a new plastic manufacturing plant in the U.S. in 2025

Proven performance in immunological and molecular diagnostics

State-of-the-art PRE-ELEC® pipette tip materials for automated liquid handling systems

Our electrically conductive plastic compounds are key factors in accurate analyses, where the material, mold, and process are optimized. Read more about our pipette tip materials→

Premix will open a modern compounding plant in North Carolina in 2025

The new plant will allow Premix’s North American customers to enjoy local production and services, ensuring faster delivery speed and high reliability. The location has been chosen to best serve the growing region of advanced manufacturing in the southeastern U.S.

The brand-new manufacturing plant with modern manufacturing lines and equipment will secure a supply of critical diagnostics materials in the U.S. and is financed by the U.S. Department of Defense, which awarded Premix a contract to establish a plastic compound manufacturing plant in North Carolina’s Gaston County.